Lab Book 2014_05_20 Hamilton Carter

Summary

The fiberglass Dewar vacuum held. The vacuum inlet was plugged to prevent any possible leaks there, and it was stored. A 480 V three phase outlet for the magnet power supply was located.

The fiberglass Dewar vacuum held. The vacuum inlet was plugged to prevent any possible leaks there, and it was stored. A 480 V three phase outlet for the magnet power supply was located.

4:30 AM Liquid

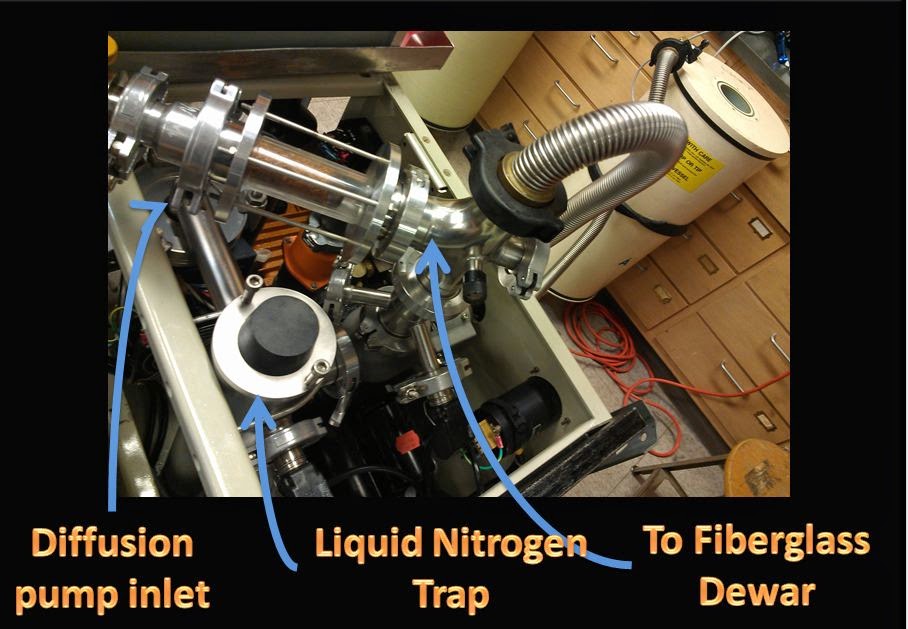

Nitrogen Trap Refilling

Refilled the liquid nitrogen trap that prevents oil vapor

from the diffusion pump from migrating opposite the intended vacuum flow into

the Dewar’s vacuum jacket. The liquid

nitrogen condenses the oil vapor in the bottom of the small container, (the

trap), that it cools.

The trap took two and a half cups of liquid nitrogen to

refill. The vacuum and leak detector

readings before and after the fill are shown below.

There was no noticeable improvement in the vacuum and leak

readings before and after the Dewar refill.

This makes sense because the Dewar still had liquid nitrogen and was

performing its intended function.

Vacuum and leak readings

throughout the day

|

Time

|

Vacuum

|

Leak

|

|

4:40

|

|

|

|

4:46

|

|

|

|

11:09

|

|

|

|

12:40

|

|

|

|

15:44

|

|

|

NOTE: The glass Dewar

is at room pressure and can be safely moved.

It’s not possible to check that the vacuum inlet valve doesn’t

leak. To prevent a possible lek even

when the valve is shut, a plug was inserted over the inlet valve.

I located a three phase 208 v plug for the magnet power

supply. I need to find a plug that will

fit this:

Comments

Post a Comment

Please leave your comments on this topic: